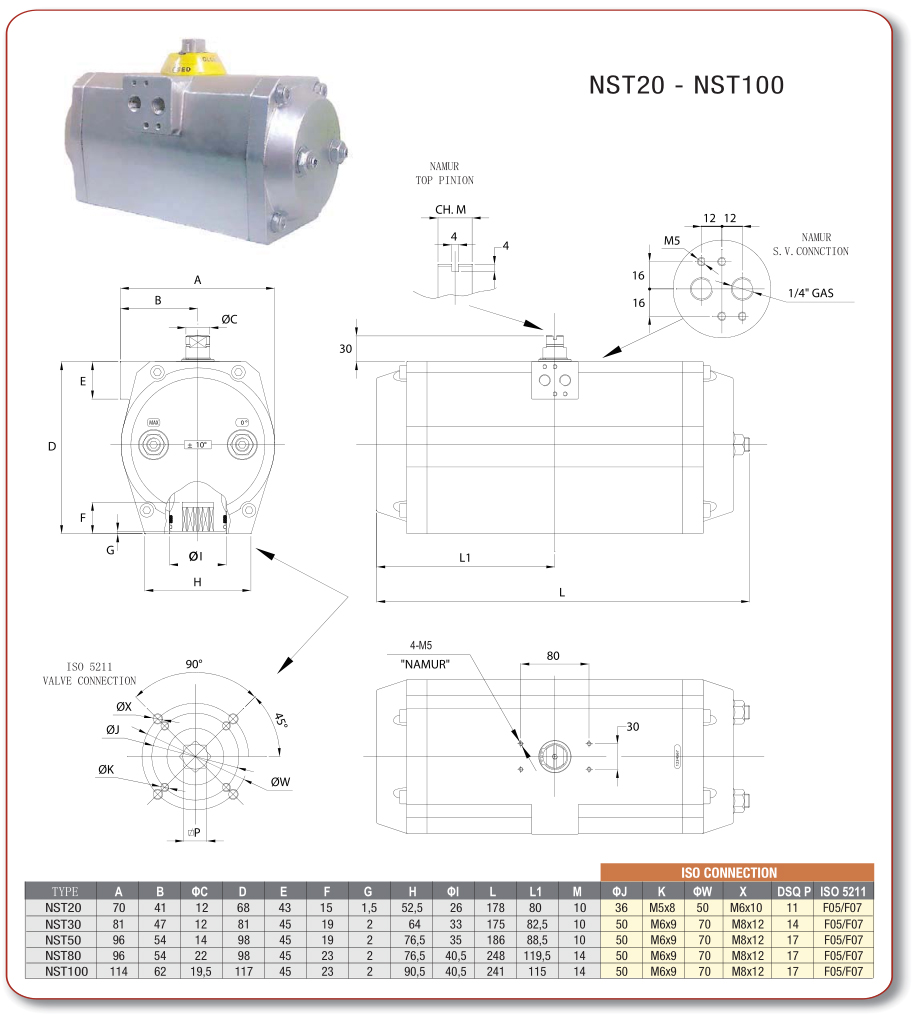

NST Series Actuators-TYPE

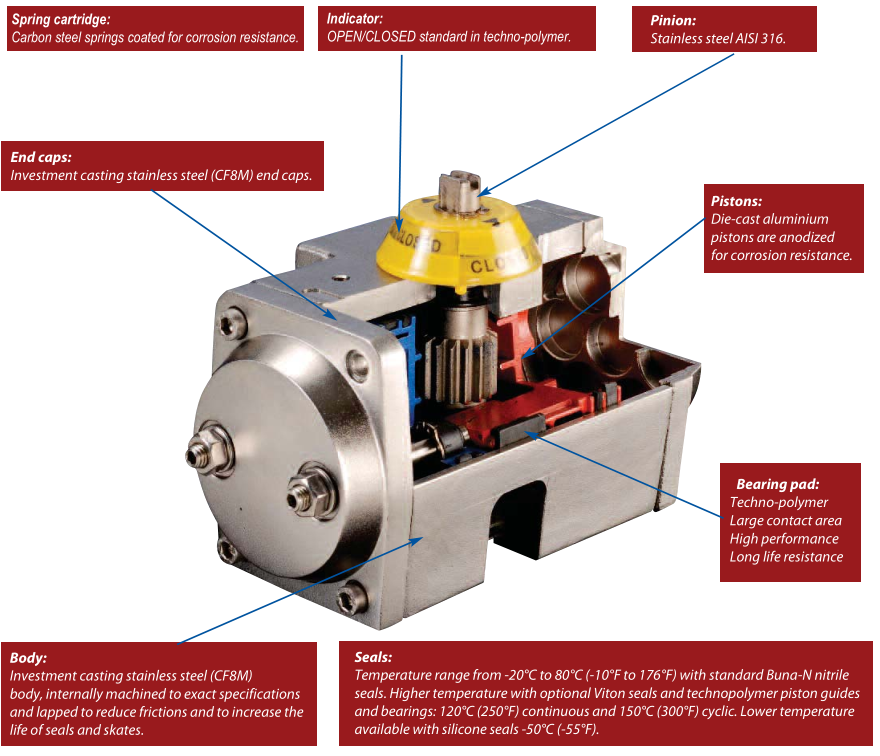

- COMPACT DESIGN: The NSEC rack & pinion stainless steel pneumatic actuator provides linear torque output in a compact design utilizing the same body and end caps for double acting and spring return units.

- AISI 316: all external components (body, end caps, pinion and fasteners) are made in stainless steel (CF8M or AISI 316) for a superior corrosion resistance.

- NAMUR: NAMUR VDI/VDE 3845 and ISO 5211 dimensions on all sizes. No special blocks are required to mount solenoid valves, limit switches or positioners.

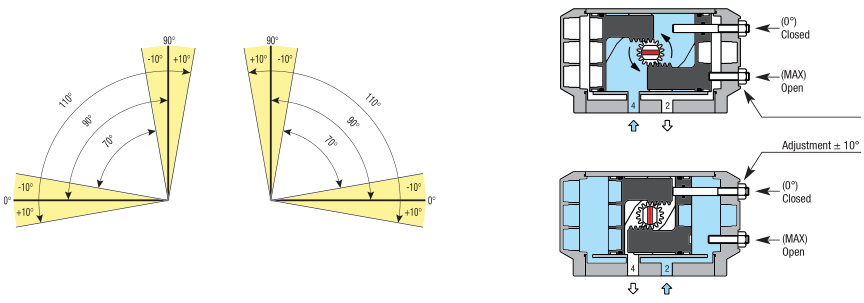

- DEGREE OF TRAVEL: The standard angle of rotation is 90°. All sizes feature a travel stop with ± 10° in both open and close directions.

- MULTIPLE OUTPUT SHAFTS: The female pinion drive is standard with a double square output drive, and optional with a double -D drive, keyed drive or custom designs to meet your specific requirements.

- HIGH CYCLE BEARINGS: Shaft bearings isolate the pinion gear from the housing and support the shaft for high cycle applications.

- PINION: The pinion teeth are engaged for the full length and stroke of the piston. The pinion height allows manual override without disturbing the indicated positions.

- HIGH VISIBILITY POSITION INDICATOR: External open/close indicator is standard.

- HIGH CYCLE LIFE WEAR PADS: Pistons incorporate double wear pads to separate the rack from the actuator wall and serve as both guide and wear bearings.

- ANTI-BLOWOUT SYSTEM: NST series pistons feature a keyway as antiblowout system.

- PRE-LOADED SPRING CARTRIDGES FOR SAFETY: Epoxy coated special steel springs are pre-loaded with non metallic materials. The stainless steel end caps fasteners are extra long to allow for spring relaxation.

- OPERATING MEDIA: Air pressure operation from 2 to 10 Bar (40 - 150PSI). Water, nitrogen and compatible hydraulic fluids may also be used to power the actuator.

- FASTENERS: All fasteners, screws and bolts made in AISI 316 / A4.

- LUBRICATION: All units are permanently lubricated at the factory with non-silicone grease.

- TRACEABILITY: All units are externally labeled with a progressive serial number for traceability.

- QUALITY: 100% of all units are factory pressure leak tested, and individually boxed for shipment.

ACTUATOR STRUCTURE

ANTI-BLOWOUT SYSTEM OF THE PINION

The anti-blowout system of the pinion is ensured thru a double protection: both with an upper c-clip and two keyways casted on the pistons. In case of unusual downward movement of the pinion, the keyways will interphere with the grooves on the pinion, therefore stopping it.

BI-DIRECTIONAL PATENTED TRAVEL STOP ILLUSTRATION

NSEC actuators feature a bi-directional travel stop. Side located stops allow a ±10° adjustment - BEST IN THE MARKET -in both closing and opening directions, so guarantee a range of adjustment between 70°and 110° of actuator stroke.

Travel stops are designed to absorb the maximum rated torque of the actuator and the maximum impact load associated with recommended speed stroke.

To increase pistons resistance both travel stops arrest the pistons in their part with the largest mass of material.

Adjustment of the counter clockwise and clockwise rotation is accomplished by turning the respective left (MAX) and right stop (0°) adjustment screws to increase or reduce output.

SPRING ASSEMBLY

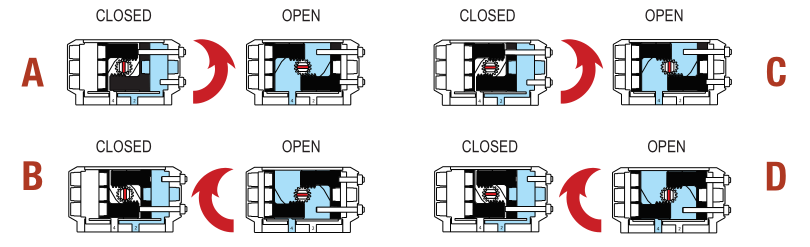

MOUNTING VARIATIONS

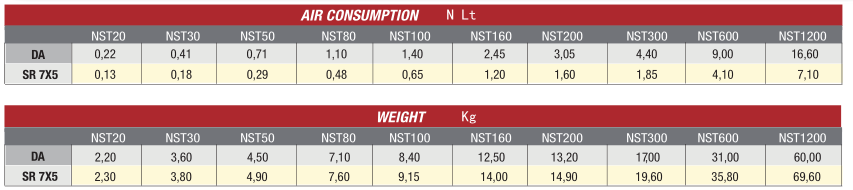

TECHNICAL DATA