BNF Series

Resilient-seated butterfly valves have widen their range of applications due to their reliability and advantages compared to traditional ball and globe valves. In particular, the NSEC BNF series are used in different industries both for ON-OFF and flow control service of any type of fluid.

Due to (thanks to) the rapid development of elastometer materials, soft seated butterfly valves are now used in Chemical and petrochemical industries, water and wastewater technology, pneumatic materials handling technology, shipbuilding, power generation industry, food industry, civil engineering – HVAC system

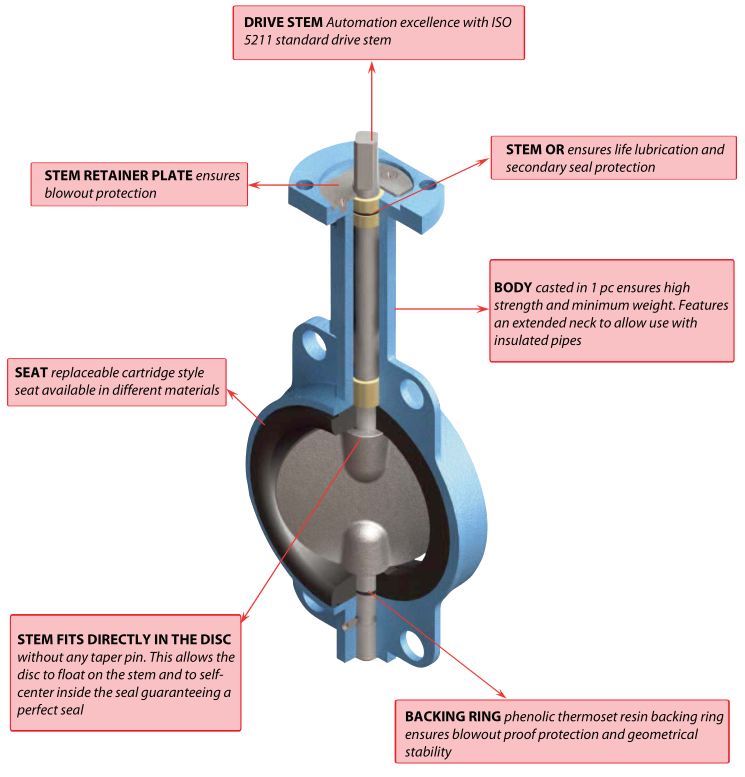

FEATURES

• Bi-directional: Tight shut off in both directions of flow, therefore valves can be mounted in both directions of flow

• Corrosion resistant as only the seat and the disc are in contact with the fluid

• Seat backing ring ensures:

- Geometric and dimensional stability

- No seat movements and therefore constant torque

- Minimal seat wear, extending seat life

- Easily field replaceable

• Stem-Disc coupling without any fastening elements (screws, pin or bolts) which could cause corrosion and failures

• Easy installation: as seat partially covers the sides of the valve body, no additional seals are required for mounting between flanges

•Suitable for installation between DIN PN 10/16 and ANSI Class 150 FF or RF pipe Flanges

• High Cv value due to double shafts and compact disc design

•Lubricated bushings valve’s low operating torque and long service life

• Automation : Top flange and square stem according ISO 5211 to easily direct mount pneumatic and electric actuators

•Epoxy Powder painted body to increase corrosion resistance

• One pc body available as Wafer or Lug designed acc. EN 593

• Extended neck body allows use with insulated pipes

• Silicon-free

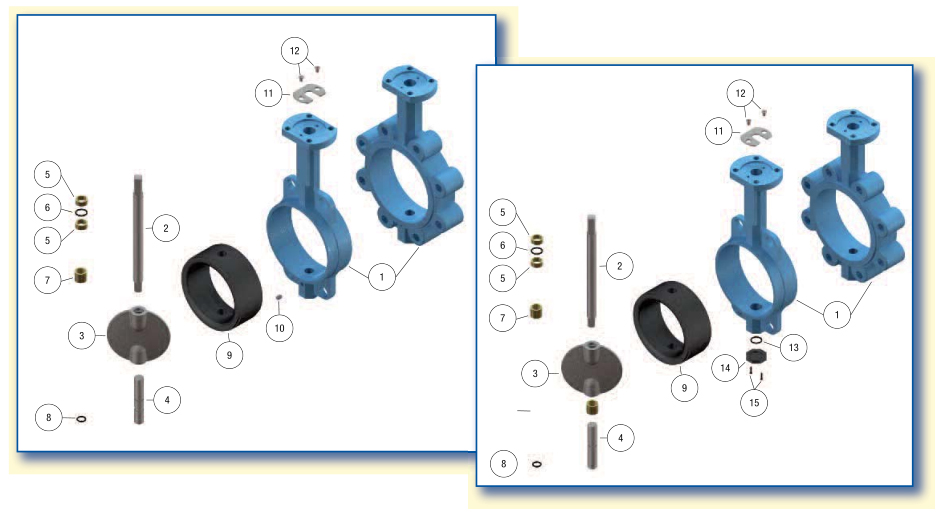

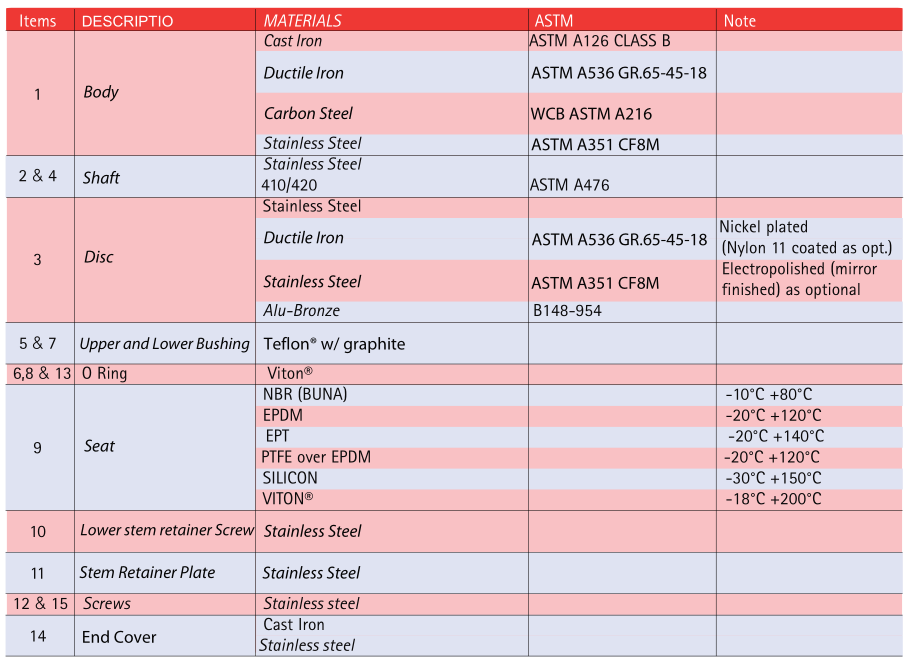

LIST OF MATERIAL

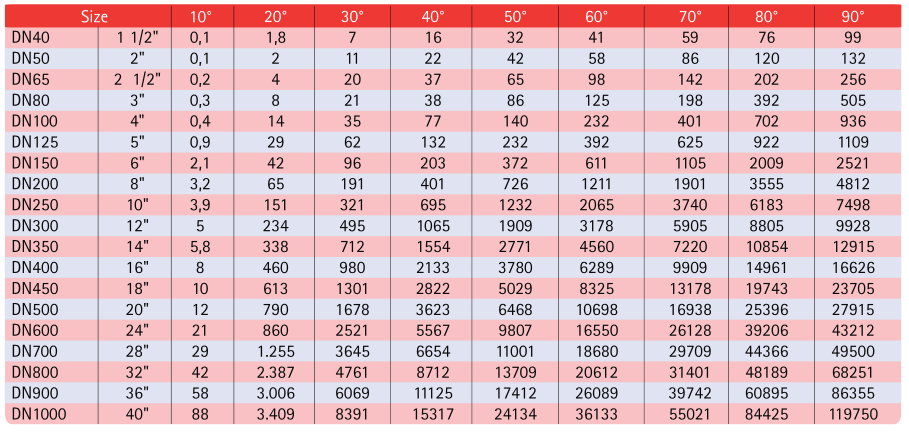

OPENING ANGLE (CV VALUE)